7 Best Blood Collection Tube Manufacturing Machine Prices You Can Find in India

Table of Contents

- Understanding Blood Collection Tube Manufacturing Machines

- Key Features to Look for in Blood Collection Tube Machines

- Comparative Analysis of Prices for Blood Tube Manufacturing Equipment

- Top Manufacturers of Blood Collection Tube Machines in India

- Cost-Effective Solutions for Blood Collection Tube Production

- Maintenance and Operational Costs of Tube Manufacturing Machines

- Streamlining Healthcare: The Advantages of a Turnkey Vacuum Blood Collection Tube Plant

- FAQS

- Conclusion

- Related Posts

Lately, there's been a real surge in the demand for blood collection tubes—probably because healthcare keeps advancing so fast and labs are doing more testing than ever. I came across a report from Research and Markets that predicts the global blood collection market will hit around $10 billion by 2025. A big chunk of this growth is thanks to new manufacturing tech popping up. Here in India, folks are looking for ways to produce these tubes more efficiently and at a lower cost, which is why there's a lot of buzz around the 'Blood Collection Tube Manufacturing Machine Price in India.' One company that’s making waves in this space is Shanghai IVEN Pharmatech Engineering Co., Ltd.—they’ve got cutting-edge production facilities and have dedicated four factories just for pharma machinery, including blood collection tube machines. In this blog, I’ll take a look at some of the best machines available right now in India, so manufacturers can produce top-quality tubes without breaking the bank while keeping up with the latest tech trends.

Understanding Blood Collection Tube Manufacturing Machines

Getting a grip on how blood collection tube manufacturing machines work can really help you out, especially if you're looking to get into the business or upgrade your setup. These machines are actually pretty important in healthcare—they’re responsible for efficiently producing those tubes we see in labs, which are crucial for running all sorts of tests.

What’s cool is that these machines automate the whole process—from forming the tubes to filling and sealing them—making things way faster and cutting down on mistakes humans might make. In India, the demand for these machines is on the rise, thanks to the booming healthcare sector and the push for better diagnostic tools.

Now, if you're thinking about buying one, it’s super important to look into the technology behind it. Modern machines tend to be more automated and precise, which means you'll get consistent quality and waste less material. Also, make sure the machine complies with international standards—no one wants safety issues or subpar products.

Here’s a little tip: don’t just buy based on the brochure. It’s really helpful to chat with industry experts or folks who are already using these machines. They can share honest insights about how reliable a particular model is and how good the after-sales support is.

And don’t forget to consider the total cost of ownership—not just the sticker price. Think about ongoing maintenance, how much it costs to operate, and the price of replacement parts. Investing in a machine backed by solid support can save you a headache (and money) down the road.

Another pro tip: head over to trade shows or exhibitions if you can. Seeing these machines in action gives you a much better idea of which one fits your needs best—plus, it’s a great chance to ask questions and get a feel for the latest tech.

Key Features to Look for in Blood Collection Tube Machines

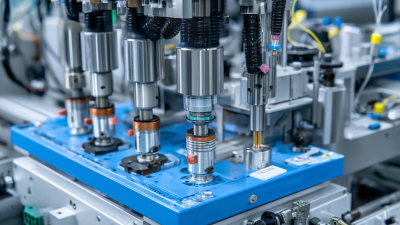

When you're choosing a machine to manufacture blood collection tubes, there are a few key features you really want to keep in mind—these can make a big difference in how smoothly things run and the quality of your products. First off, take a good look at the machine’s production capacity. I remember reading a market report by Grand View Research, which predicted that demand for blood collection tubes is going to skyrocket — they’re estimating the market could hit around USD 5 billion by 2028. So, having a machine that can pump out lots of tubes quickly, say over 120 per minute, is pretty much essential if you want to stay ahead of the game.

Another thing to think about is how precise and automated the machine is. High-end models with servo motors and automated quality control really help keep the quality consistent and cut down on waste. A report from Mordor Intelligence even mentions that automating manufacturing processes can boost productivity by up to 30%. Oh, and don’t forget about how easy it is to maintain the machine and whether spare parts are readily available. These little details can save you a lot of headaches down the line, preventing downtime and extending the lifespan of your equipment.

All in all, taking a close look at these features when you’re shopping around for a blood collection tube manufacturing machine can really pay off. It’s not just about getting things up and running quickly, but also about ensuring long-term efficiency and staying competitive in the healthcare market—that’s what really counts.

Comparative Analysis of Prices for Blood Tube Manufacturing Equipment

When you're looking into equipment for making blood collection tubes, comparing prices really becomes a key part of finding a good deal—without sacrificing quality, of course. From what I’ve seen in industry reports, the market for these machines in India is definitely on the rise. Prices tend to range anywhere from around ₹15 lakh up to ₹50 lakh, depending on the features and tech involved. The major factors that drive the cost include how automated the machine is, how much it can produce, and the types of materials it uses.

Take companies like Shanghai IVEN Pharmatech Engineering Co., Ltd., for example—these guys run four factories focused just on blood collection tube machinery. They often offer pretty advanced equipment at competitive prices, which can be a big draw for buyers. What’s nice about their approach is that they focus on quality, so you’re pretty much guaranteed durable, reliable machines—super important in the medical field. I recently read that automated systems can boost production efficiency by up to 40%. Sure, they might cost a bit more upfront, but honestly, the productivity gains make it worth considering.

**Tip:** When you're checking out potential suppliers, don’t just focus on the price—look at the customer support and warranty services too. Good quality machinery usually comes with proper training and maintenance support, which can save you a bunch of headaches down the road. **Tip:** And hey, always try to get some sample production runs before making a big purchase. This way, you can see how the machine performs firsthand and make sure it meets all the medical standards you need.

Comparative Analysis of Blood Collection Tube Manufacturing Machine Prices in India

This chart illustrates the comparative prices of various blood collection tube manufacturing machines available in India, showcasing how their prices vary based on different specifications and capacities.

Top Manufacturers of Blood Collection Tube Machines in India

When it comes to making blood collection tubes, India has really grown into a pretty big hub. There are quite a few companies out there that focus on creating top-notch manufacturing machinery. The best players in the game put a lot of emphasis on cutting-edge technology and reliability — making sure their machines meet all those strict healthcare standards. For instance, companies like BPL Medical Technologies stand out because they offer innovative solutions designed specifically to make tube production easier. Their machines are built to simplify the whole process—mixing automation with user-friendly controls—which helps boost both productivity and consistency.

Then there’s AIT, another major name in this space. They’re known for their high-end blood collection tube machines that deliver precision engineering. They have different models suited for various scales of production, so whether you're running a small setup or a large factory, they’ve got you covered. What’s pretty cool is that AIT keeps investing in research and development, so they stay ahead of the curve—offering machines that are not just cost-effective but also eco-friendly. As demand for reliable blood collection systems in India keeps climbing, these manufacturers are really playing a vital role in supplying the essential equipment that healthcare needs right now.

Cost-Effective Solutions for Blood Collection Tube Production

With the medical industry evolving so quickly, the demand for blood collection tubes has really taken off. That means there's a big need for manufacturing solutions that are both efficient and budget-friendly. When you're looking into blood collection tube machines here in India, you'll find a wide range of prices, so it’s pretty important to find that sweet spot where quality meets affordability. A recent industry report from ResearchAndMarkets even says the global market for these tubes is growing at about 7.4% CAGR from 2021 to 2026 — which is a pretty promising sign for newcomers trying to carve out a space by adopting newer, smarter production methods.

Now, if you're thinking about investing in one of these machines, don’t forget to balance the initial cost against what you'll save down the line. Going for a high-quality machine might seem pricey at first, but it can pay off in the long run by cutting down on downtime and lowering your maintenance bills. Experts often recommend looking for equipment with automation features — they boost your production speed and help reduce human errors, which is a huge plus.

A few tips? Do your homework and compare different machines and their specs thoroughly. Also, think about the return on investment (ROI) — it's not just about what you pay upfront but also the ongoing operating and maintenance costs. Staying updated on the latest tech trends can also help you future-proof your setup, making sure your business remains competitive as the market grows. All in all, being strategic with your purchase choices can really set you apart in this booming industry.

7 Best Blood Collection Tube Manufacturing Machine Prices You Can Find in India - Cost-Effective Solutions for Blood Collection Tube Production

| Machine Type | Production Capacity (Tubes/Hour) | Price Range (INR) | Features |

|---|---|---|---|

| Automatic Tube Filling Machine | 1200 | ₹1,500,000 - ₹2,000,000 | User-friendly interface, high-speed operation |

| Semi-Automatic Tube Sealing Machine | 800 | ₹800,000 - ₹1,200,000 | Cost-effective, requires minimal operator intervention |

| Full Automatic Tube Production Line | 2000 | ₹4,500,000 - ₹5,500,000 | Complete automation for high efficiency |

| Manual Tube Filling Machine | 400 | ₹300,000 - ₹500,000 | Compact design, suitable for small-scale production |

| Automated Labeling Machine | 1000 | ₹1,200,000 - ₹1,800,000 | High-speed labeling, adjustable settings |

| Quality Control Testing Machine | N/A | ₹1,000,000 - ₹1,600,000 | Advanced testing technology, reliable results |

| Tube Decapper and Re-capper Machine | 600 | ₹500,000 - ₹700,000 | Easy to operate, enhances production efficiency |

Maintenance and Operational Costs of Tube Manufacturing Machines

When you're thinking about investing in blood collection tube manufacturing machines, it's really important to look beyond just the upfront cost. Sure, those machines might seem affordable at first glance, but don’t forget about the ongoing expenses. Over time, things like maintenance and operational costs can really add up and impact your profits. Regular upkeep is a must—things like routine checkups, swapping out worn parts, and calibration—they all keep the machines running smoothly and extend their life. It’s a bit of a pain, but totally worth it in the long run.

Then there’s the day-to-day operating costs you’ve gotta consider. Things like how much energy they use, the wages for labor, and the cost of raw materials. Usually, the more efficient the machine—for example, ones that are mostly automated and eco-friendly—the more money you save down the line. Plus, going for reliable machines can help reduce unexpected breakdowns, saving you even more cash—and headaches. So, if you really get what’s involved, you can make smarter choices that fit your budget and help you reach your production targets without surprises along the way.

Streamlining Healthcare: The Advantages of a Turnkey Vacuum Blood Collection Tube Plant

In the rapidly evolving landscape of healthcare, efficiency and reliability are of utmost importance. One of the most significant advancements in this domain is the development of turnkey vacuum blood collection tube plants. These specialized facilities streamline the production process, providing healthcare providers with high-quality components essential for safe and effective blood collection. IVEN Pharmatech stands at the forefront of this innovation, offering integrated engineering solutions tailored to meet the needs of pharmaceutical and medical factories globally.

A turnkey plant from IVEN Pharmatech eliminates the complexities often associated with setting up production lines. These plants are designed in compliance with international standards such as EU GMP, US FDA cGMP, PICS, and WHO GMP, ensuring that every aspect of the manufacturing process adheres to the highest quality norms. By providing a comprehensive solution that encompasses everything from design to installation, IVEN Pharmatech helps businesses focus on their core operations while ensuring that they have access to reliable and efficient production capabilities.

The advantages of adopting such a turnkey system are immense. It not only saves time and reduces operational costs but also enhances product consistency and quality. As healthcare demands continue to increase, having a dependable source for medical materials like vacuum blood collection tubes becomes essential. IVEN Pharmatech’s expertise enables healthcare providers to meet these challenges head-on, ensuring that the vital components required for patient care are available when needed, thereby improving overall healthcare outcomes.

FAQS

: The demand for blood collection tubes is significantly increasing due to advancements in the medical industry, prompting a need for efficient and cost-effective manufacturing solutions.

Businesses should weigh the upfront costs against long-term savings, look for automation features to enhance production speed, and minimize the risk of human error.

According to a recent industry report, the global market for blood collection tubes is expected to grow at a CAGR of 7.4% from 2021 to 2026.

Investing in high-quality machinery can reduce production downtime and lower maintenance costs, ultimately increasing efficiency in the manufacturing process.

The total cost of ownership should include the initial price, operating expenses, maintenance costs, and potential return on investment (ROI).

Regular maintenance is crucial to ensure optimal performance and longevity of the equipment, which can include inspections, parts replacement, and calibration.

Operational costs include energy consumption, labor costs, and raw material expenses, all of which impact overall profitability.

Manufacturers can control costs by selecting machines that offer automation, energy efficiency, and a reputation for reliability to reduce downtime.

Staying informed about technological advancements can provide insights into future-proofing manufacturing setups and ensuring competitiveness in the market.

Conducting thorough market research and making strategic purchasing decisions can help businesses remain competitive and maximize profits in the growing market.

Conclusion

If you're trying to get a good grip on how blood collection tubes are made, it helps to look at a few key things—like what features matter most, how much the machines cost, and what’s involved in keeping them running smoothly. In this blog, we’re diving into a side-by-side look at the prices for blood tube manufacturing equipment, especially focusing on the 'Blood Collection Tube Manufacturing Machine Price in India.' We’ll highlight some of the top manufacturers and point out options that give you the best bang for your buck. This way, you’ll get a clear picture of the market in India, helping you make smarter decisions for your production needs.

One name that really stands out in this space is Shanghai IVEN Pharmatech Engineering Co., Ltd. They’ve got four factories dedicated to making pharmaceutical machinery, including blood collection tube manufacturing equipment. Known for their commitment to quality and innovation, they show how technology is advancing, making it possible to keep costs down while still hitting high standards in production.

Related Posts

-

The Definitive Handbook to Automated Inspection Machines in the Pharma Industry

-

Ultimate Checklist for Selecting the Right Vial Filling Equipment

-

How to Maximize Production Efficiency with an IV Cannula Making Machine: A Data-Driven Approach

-

Ultimate Checklist for Choosing the Best Herb Extraction Machine for Your Business Needs

-

Understanding the Essentials of Automated Filter Tube Production Techniques

-

Ultimate Guide to Efficient Glas Bottle Packaging Machines for Your Production Line

Blog Tags: