How to Choose the Right Syringe Filter Manufacturers for Your Laboratory Needs

Table of Contents

- Understanding Your Laboratory's Specific Filtration Requirements

- Identifying Key Qualities in Syringe Filter Manufacturers

- Evaluating Manufacturer Reputation and Customer Reviews

- Exploring Material Compatibility and Filter Specifications

- Comparing Pricing and Bulk Purchase Options

- Assessing Customer Support and Technical Assistance Availability

- Maximizing Efficiency in Pharmaceutical Production: The Role of Syringe Assembling Machines

- FAQS

- Conclusion

- Related Posts

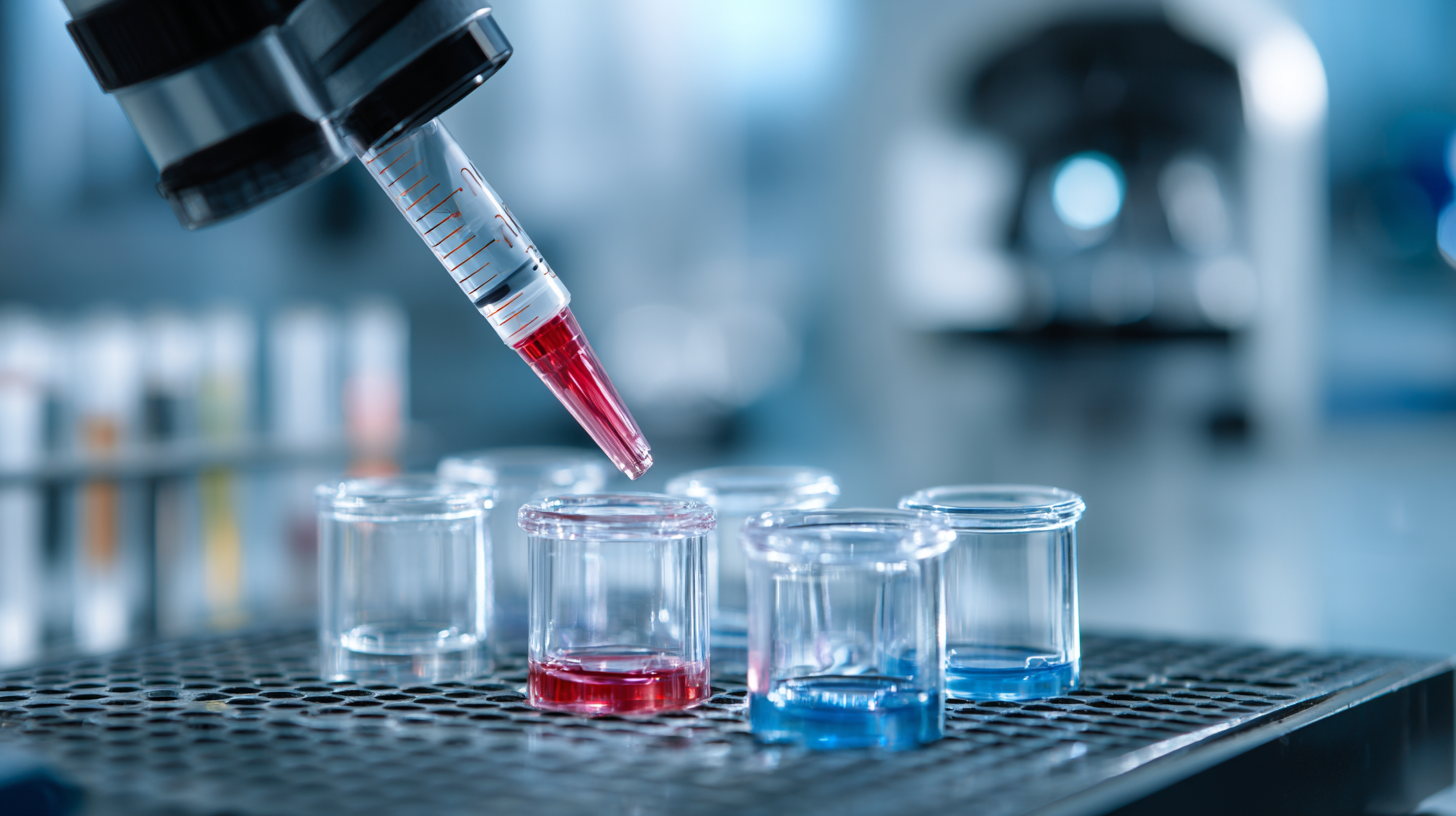

Picking the right syringe filter manufacturer really matters if your lab wants to stay on top of accuracy and dependability in your experiments and projects. Honestly, with so many options out there, it can feel a bit overwhelming — you’ve got to weigh things like how reputable the manufacturer is, the overall quality of their products, and whether they follow industry standards.

Take Shanghai IVEN Pharmatech Engineering Co., Ltd., for example. They’re pretty well-known for their expertise in pharmaceutical machinery and equipment, making them a trusted name in the field. They’ve got four professional factories, not just making syringe filters but also blood collection tubes and water treatment gear, which shows they’re serious about blending innovation with reliability.

In this blog, I’ll walk you through some key points to think about when choosing a syringe filter manufacturer — so you can find one that really matches your lab’s needs and keeps everything running smoothly and according to all the right standards.

Understanding Your Laboratory's Specific Filtration Requirements

When you're choosing a syringe filter manufacturer for your lab, it's really important to get a clear idea of what your specific filtration needs are. Every lab’s a bit different—depending on what kind of samples you're working with, the filtration techniques you prefer, and the rules you need to follow. For example, if you're dealing with pharmaceuticals, compliance and data integrity become *huge* priorities. You’ll want filters that meet strict standards and can handle rigorous testing. That way, you’re sure your results are solid and trustworthy, which honestly makes a real difference in research quality.

On top of that, technology in filtration is moving fast. The new systems out there are not just more efficient but also safer and more eco-friendly. If you check out the latest innovations—things like high-performance membranes and easier-to-use filtration setups—you’ll find it easier to pick a manufacturer that’s offering the most up-to-date, tailored solutions for your needs. Since the market's expected to grow quite a bit, choosing the right supplier isn’t just smart—it's essential to keep things running smoothly and safely.

Laboratory Syringe Filter Needs Overview

This bar chart illustrates the specific filtration requirements in a laboratory setting, indicating how many users are utilizing different types of filtration methods. Microfiltration is the most utilized method, followed by sample preparation and sterilization, reflecting the varied needs of laboratory processes.

Identifying Key Qualities in Syringe Filter Manufacturers

When you're choosing syringe filter manufacturers for your lab work, it’s pretty important to keep a few key things in mind — stuff that can really make a difference in how reliable and quality your research turns out. First off, you wanna look at their reputation in the industry. Usually, the well-known companies have tons of experience under their belt and a solid track record of delivering top-notch products. If you see certifications and that they comply with industry standards, that’s a good sign too — it means their filters meet strict quality checks, which is crucial for safety and trust in your lab procedures.

Another thing to think about is the variety of filters they offer. A good manufacturer should have a wide range of materials, pore sizes, and configurations, so you can find exactly what you need for different tasks — whether it’s preparing samples or sterilizing solutions. Plus, customer support really matters. Manufacturers who are quick to respond, offer technical help, and provide options for product customization or after-sales service can make your life a lot easier and help keep your lab running smoothly. If you keep these points in mind, you'll be in a better position to pick the right syringe filter supplier for your needs.

Evaluating Manufacturer Reputation and Customer Reviews

When you're choosing a syringe filter manufacturer, it's super important to check out their reputation and read some customer reviews. Honestly, a company with a solid rep usually means they’re consistent with their product quality and that they handle customer concerns pretty well. It helps if they’ve been around for years—think of it like a badge of trust that they’ve proven they can adapt and stick around through industry changes.

Plus, those customer reviews? They’re gold. They give you a real sneak peek into how the filters perform in real lab settings. Look for common themes—are folks happy with how well the filters do their job? Do they like the variety of options to choose from, especially if you’ve got specific research needs? Don’t forget to see how quick and helpful the manufacturer's customer support is, because that can tell you a lot about how much they care about making sure you’re satisfied. Do your homework by checking reviews and industry standing, and you'll be in a much better spot to pick what’s best for your lab’s needs.

Exploring Material Compatibility and Filter Specifications

When you're choosing the right syringe filter manufacturers for your lab, it's really important to think about how well the materials match up with your specific needs. Different filter materials can react differently with solvents, chemicals, or biological samples you might be working with. For example, nylon filters are great for water-based samples, but they’re not so hot when it comes to organic solvents. On the flip side, PTFE filters are fantastic for handling those tougher, more aggressive solvents—making them a favorite in organic chemistry labs. Grasping these compatibility details helps you get smoother filtration and results you can trust.

Tip: Don’t forget to check out the manufacturer’s datasheets—they usually have all the nitty-gritty info on material compatibility and specifications. It’s worth reading through so you can pick the right syringe filter for your particular setup.

Also, pay attention to specs like pore size and membrane thickness because they really impact how well your filtration works. Most syringe filters have pore sizes from around 0.22 microns up to 5 microns. Smaller pores are better for removing tiny particles, especially if you're aiming for sterile solutions. Picking the right pore size not only helps you get the results you want but also means your filters last longer, which is a big plus for keeping your lab running smoothly.

Tip: Before you go all-in with a big order, do a quick test with a few of your actual samples. This way, you can make sure the filters are up to the task without wasting resources on something that might not fit your needs.

How to Choose the Right Syringe Filter Manufacturers for Your Laboratory Needs

| Material Compatibility | Pore Size (µm) | Filter Diameter (mm) | Max Operating Temperature (°C) | Sterility Options | Applications |

|---|---|---|---|---|---|

| Polyethylene | 0.22 | 25 | 80 | Yes | Biological Sample Filtration |

| PTFE | 0.45 | 30 | 120 | No | Chemical Filtration |

| Nylon | 0.2 | 25 | 90 | Yes | Sample Preparation |

| Cellulose Acetate | 0.45 | 25 | 70 | Yes | Aqueous Solutions |

| PVDF | 0.1 | 25 | 120 | No | Filtration of Gases and Solvents |

Comparing Pricing and Bulk Purchase Options

When you're trying to pick the right syringe filter manufacturers for your lab, things like price and buying in bulk tend to be pretty important. More and more labs are going the bulk route to save a bit of cash—some recent studies actually show you can cut costs by up to 30% when you buy consumables in larger quantities instead of going piece by piece. That’s especially handy for stuff you use a lot of, like syringe filters, because staying stocked up without breaking the bank keeps everything running smoothly.

And it’s not just labs that's jumping on this bandwagon; other areas are doing it too. Take the recent comparison of local beef prices—buying in bulk really does pay off compared to pricey individual cuts. Likewise, labs that opt for bulk purchases of syringe filters can enjoy those savings while making sure they never run out of what they need. With tight budgets these days, making smart choices about suppliers and buying larger quantities is more important than ever if you want things to run without a hitch.

Assessing Customer Support and Technical Assistance Availability

When you're on the hunt for a syringe filter manufacturer, one thing you definitely want to pay attention to is how good their customer support and tech help actually are. I read a recent report from Grand View Research, and it turns out that about two-thirds of lab folks said quick, responsive service really makes a difference in how satisfied they are with their supplier. Because let’s be honest—when you have urgent filtration needs, having support that’s there for you can honestly save your day and cut down on delays.

If you want to make sure you’re picking the right company, don’t be shy about reaching out to their support team with some specific questions about their products. See how fast they get back to you and whether they give clear, useful answers. That’ll give you a good idea of how committed they are to backing up their customers.

By the way, it’s also smart to ask if they have plenty of technical documents—manuals, application notes, troubleshooting guides. A solid manufacturer should have all that ready to go, making your life way easier.

And don’t forget to check out reviews and feedback from other labs. Reading about other people’s experiences can really help you get a sense of how reliable and supportive the manufacturer actually is after you buy.

Oh, and if you want to get a real feel for things, try using LinkedIn or similar platforms to connect with other professionals. Their firsthand stories can be super helpful when you’re making your decision.

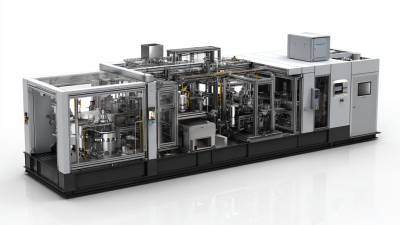

Maximizing Efficiency in Pharmaceutical Production: The Role of Syringe Assembling Machines

In the rapidly evolving pharmaceutical industry, maximizing production efficiency is crucial to meeting the ever-increasing demand for high-quality medical devices, such as syringes. The role of syringe assembling machines has become indispensable in streamlining production processes and ensuring consistency in output. According to a recent report by Grand View Research, the global syringe market is expected to reach USD 12.2 billion by 2027, driven by the growing prevalence of chronic diseases and the rising number of vaccinations. This growth trajectory underscores the need for automated solutions that can enhance efficiency and reduce operational costs.

Our Syringe Assembling Machine is designed specifically for this purpose, offering the capability to automatically assemble various types of syringes, including luer slip and luer lock options. The machine is equipped with an advanced LCD display that allows operators to monitor feeding speed and independently adjust assembly rates, ensuring a seamless production flow. With features such as electronic counting, low power consumption, and minimal noise levels, this machine not only supports stable operations but also aligns with GMP standards, making it an ideal choice for modern pharmaceutical facilities.

Moreover, as production demands increase, the efficiency of syringe assembling machines has a direct impact on the overall success of pharmaceutical companies. According to industry experts, automating syringe assembly can increase production rates by up to 50%, allowing manufacturers to meet tight deadlines without compromising quality. With such innovations at their disposal, companies can enhance their competitive edge and better serve the healthcare market.

FAQS

: Evaluating a manufacturer's reputation is crucial as it often indicates consistent product quality and reliable customer service, which can significantly influence your laboratory's performance.

Customer reviews provide insights into real-world product performance and user satisfaction, helping you understand both the effectiveness of the filters and the manufacturer's responsiveness to customer concerns.

You should consider the compatibility of different filtering materials with the solvents, chemicals, and biological samples you work with, as this affects filtration efficiency and results.

Nylon filters are suitable for aqueous samples but not for organic solvents, while PTFE filters are ideal for aggressive solvents and are often used in organic chemistry labs.

Filter specifications like pore size and membrane thickness are crucial; smaller pore sizes effectively remove particulates, contributing to better filtration results and prolonging filter life.

It is advisable to conduct a preliminary test with your intended samples to ensure that the selected filter meets your specific filtration requirements.

You should consult the manufacturer's datasheets for in-depth information regarding filter material and compatibility, aiding in your decision-making process.

Common pore sizes for syringe filters range from 0.22 microns to 5 microns, with smaller sizes being more effective for sterile solutions.

A manufacturer's responsiveness to customer concerns and their ability to adapt to industry changes often reflect their commitment to quality and customer satisfaction.

Conclusion

When you're trying to pick the right syringe filter manufacturers for your lab, it's pretty important to really understand what your filtration needs are. You know, figuring out what qualities matter most—like whether they follow quality standards and use innovative tech. It can also be super helpful to check out reviews from other customers; they often give a good sense of how reliable and performance-driven a manufacturer is. Oh, and don't forget to look into the materials and specs of the filters to make sure they’re compatible with what you’re working on in the lab.

Also, keep an eye on pricing and whether they offer bulk deals—that can really help stretch your budget. And of course, good customer support and tech help are a must-have. Take a company like Shanghai IVEN Pharmatech Engineering Co., Ltd., for example—they’ve got dedicated factories that focus on pharmaceutical machinery. They know that quality and support are key when it comes to meeting the varied needs of labs. Following these tips should help you choose a supplier who can really boost your lab’s efficiency and make your work a whole lot smoother.

Related Posts

-

Ultimate Checklist for Choosing the Best Herb Extraction Machine for Your Business Needs

-

7 Best Blood Collection Tube Manufacturing Machine Prices You Can Find in India

-

The Definitive Handbook to Automated Inspection Machines in the Pharma Industry

-

Navigating Import Export Certifications for Best Pen Injector Assembly Line Success

-

Exploring After-Sales Service Benefits and Future Innovations in Dry Powder Filling Machinery

-

Unlocking Efficiency: The Transformative Benefits of Blow Fill Seal Machines in Modern Manufacturing

Blog Tags: