7 Essential Tips for Choosing the Right Blow Fill Seal Manufacturers for Your Business

Table of Contents

- Identifying Your Business Needs for Blow Fill Seal Solutions

- Evaluating Manufacturers' Experience and Expertise in the Industry

- Assessing Quality Standards and Compliance in Blow Fill Seal Production

- Understanding the Importance of Customization Options Available

- Reviewing Customer Feedback and Case Studies for Insight

- Analyzing Cost Structures and Long-Term Financial Commitments

- Innovative BFS Solutions: Revolutionizing Intravenous and Ampoule Product Manufacturing

- FAQS

- Conclusion

- Related Posts

You know, in today’s super busy world of pharmaceuticals, there’s actually a pretty big demand for innovative packaging solutions—like, it’s never been more important. I recently saw a report from MarketsandMarkets that said the global Blow Fill Seal (BFS) market is expected to jump from about $3.64 billion in 2020 to around $5.33 billion by 2025, growing at roughly 7.8% annually. That kind of growth really pushes companies to be more careful when choosing their BFS manufacturers—making sure they match their production needs and meet all the quality standards. Among all the players out there, Shanghai IVEN Pharmatech really stands out, with four top-notch factories specializing in different kinds of pharmaceutical machinery, including some pretty advanced BFS systems. When businesses know what to look for in a BFS manufacturer—like quality, reliability, and technology—they can run things smoother, producing high-quality products that stick to all the strict regulations. It’s all about making smart choices to stay ahead in this competitive field, right?

Identifying Your Business Needs for Blow Fill Seal Solutions

When you're picking a Blow Fill Seal (BFS) manufacturer, the first thing you should really do is figure out what your specific business needs are. I mean, understanding what you need involves looking at things like the types of products you want to package, how big your production runs are, and the industry standards you have to follow. For example, pharma companies usually need super precise machinery to keep products safe and compliant, whereas other manufacturers might care more about saving costs and getting products out quickly. If you can clearly lay out these needs, it'll be way easier to narrow down your options and properly check out what each manufacturer can offer.

Here at Shanghai IVEN Pharmatech Engineering Co., Ltd., we focus on creating customized Blow Fill Seal solutions. We’ve got four dedicated factories that work on pharmaceutical machinery, blood collection tubes, and water treatment equipment. Our know-how helps us meet a wide range of industry needs with high-quality, dependable equipment that boosts your production. Working with us means you’ll get access to cutting-edge technology and flexible options tailored just for you, making sure your business hits its goals and stays competitive in this busy market.

7 Essential Tips for Choosing the Right Blow Fill Seal Manufacturers for Your Business

| Criteria | Description | Importance Level |

|---|---|---|

| Experience and Expertise | Evaluate the manufacturer’s years in the industry and their specialization in blow fill seal technology. | High |

| Quality Assurance | Look for manufacturers with strong quality control processes and certifications. | High |

| Technology Utilization | Assess if the manufacturer uses advanced machinery and technology in their production process. | Medium |

| Customer Support | Review the level of customer service and support provided throughout the partnership. | High |

| Cost-Effectiveness | Analyze pricing structures without compromising quality for budget considerations. | Medium |

| Scalability | Ensure the manufacturer can scale production based on your business growth. | High |

| Reputation | Research the manufacturer's market reputation and past client testimonials. | High |

Evaluating Manufacturers' Experience and Expertise in the Industry

When you're on the hunt for a blow fill seal (BFS) manufacturer, it's super important to really pay attention to their experience and know-how in the industry. I mean, according to a report by MarketsandMarkets, the BFS tech market is projected to jump from around USD 4.6 billion in 2020 to a staggering USD 6.7 billion by 2025. That growth shows just how much folks are craving more efficient and safer packaging options. As this market keeps evolving, teaming up with a manufacturer that’s been around the block a few times can seriously give your business the edge it needs.

Here’s a little tip: look for manufacturers who've got a solid track record with BFS tech. Ideally, they should have at least 5 to 10 years of hands-on experience and a bunch of success stories across different fields—stuff like pharmaceuticals, cosmetics, or food packaging. That way, you can be pretty confident they’re not just following the standard playbook but actually know how to handle those tricky, unique packaging challenges. Plus, it means they’re likely to stick to industry standards and have the expertise to tackle whatever comes their way.

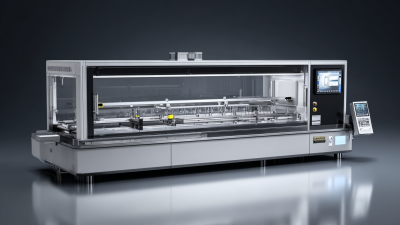

Another key thing to check out is their tech game—what kind of equipment and innovations they’re working with. Having cutting-edge machinery and staying ahead with tech can really make a difference in quality control. A survey from Grand View Research points out that manufacturers who invest in automation and new tech tend to produce more, with fewer errors. Not bad, huh?

Here’s what to ask: Find out what kind of machines and tech they’re using, and see if they’re into sustainable practices and can handle changing regulations. A manufacturer that’s on top of these trends is probably more likely to support your business’s long-term goals and overall sustainability plans.

Assessing Quality Standards and Compliance in Blow Fill Seal Production

When you're choosing a blow fill seal (BFS) manufacturer for your business, it’s really important to pay attention to their quality standards and whether they follow industry regulations. A good starting point is to check if they stick to current Good Manufacturing Practices (cGMP) and can meet those specific biopharmaceutical standards we hear about all the time. Also, look for manufacturers that are using the latest BFS tech — not only does this boost sterility during packaging, but it also helps keep the product’s integrity intact. And with more manufacturers moving towards automated systems, it’s a smart move because it cuts down on human errors and makes the whole production process smoother and more efficient.

Don’t forget to also take a close look at how they handle quality control. A manufacturer that has a solid quality-by-design approach and uses automated inspection tools can really give you confidence that the products are top-notch. Understanding their methods for checking package integrity — especially if they follow the latest USP guidelines — is key to making sure your products stay compliant and safe for the market. Working with manufacturers who prioritize these quality checks is crucial if you want to keep up those high standards in the biopharmaceutical world.

Understanding the Importance of Customization Options Available

When you're choosing a Blow Fill Seal (BFS) manufacturer for your business, it's really important to get a good handle on the customization options they offer. See, being able to customize your machinery isn’t just about fitting your specific production needs — it can actually boost efficiency and improve the quality of your products too. Take a reputable player like Shanghai IVEN Pharmatech Engineering Co., Ltd., for example. They’ve got multiple factories, each specialized in different areas like pharma machinery and water treatment equipment, which means they can really tailor solutions to what you need. That kind of flexibility is a game-changer because it helps you optimize your whole production process based on your unique requirements.

Plus, having a manufacturer that’s willing to provide custom solutions can really make a difference in how smoothly things run on your end. Customization might mean tweaking machine specs, adding in some cutting-edge tech, or modifying designs to meet all the regulatory standards — whatever it takes. When you go with a company like IVEN Pharmatech that values those custom options, you can be pretty confident that your equipment will be up-to-date with industry standards and fully aligned with your specific goals. That way, you end up with better performance and happier customers in the long run.

Customization Options Offered by Blow Fill Seal Manufacturers

Reviewing Customer Feedback and Case Studies for Insight

When you're choosing a blow fill seal (BFS) manufacturer for your business, it's so helpful to look into what other customers are saying and check out some case studies. Recently, an industry report pointed out that about 65% of companies say customer reviews are super important when deciding on vendors. That really puts a spotlight on how much firsthand experiences matter—good reviews can show that a manufacturer is reliable and delivers quality products. Talking to past clients or reading testimonials online can give you a pretty good sense of whether a manufacturer is consistent and efficient, which is especially crucial when it comes to meeting strict standards in pharmaceuticals and food products.

Also, digging into case studies can really reveal some interesting applications and operational efficiencies that different BFS technologies can enable. For example, one case study from a top BFS maker showed a 30% cut in both production time and costs for a big pharma client. Looking at these real-world examples helps you get a clearer picture of whether a manufacturer can actually meet your specific needs. In an industry where precision and compliance are non-negotiable, relying on documented success stories can seriously influence your decision-making process when considering BFS options.

Analyzing Cost Structures and Long-Term Financial Commitments

When you're choosing a blow fill seal (BFS) manufacturer,

it's really important to get a good sense of their cost structure.

This isn’t just about looking at the price—they often vary quite a bit depending on things like the quality of the materials,

how efficient their equipment is, and the cost of labor.

It’s a smart move to talk directly with potential manufacturers about their pricing setups because that can give you

a clearer picture of what you might be committing to long-term.

And honestly, if their prices are transparent, it’s usually a good sign—they tend to be more reliable and straightforward.

Another thing I’d definitely keep in mind is how much the manufacturer invests in new technology.

Sure, cutting-edge BFS equipment might cost more upfront, but in the long run, it usually pays off through

lower operational costs and less waste. Going with a manufacturer who’s into innovation means your business can stay competitive and even grow.

Plus, it’s worth thinking about whether they can ramp up production if your needs change.

Flexibility here can save you a lot of headaches and money down the line—no point signing on with a partner who can’t adapt

as your demand evolves.

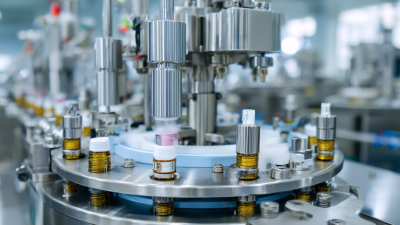

Innovative BFS Solutions: Revolutionizing Intravenous and Ampoule Product Manufacturing

The healthcare industry is undergoing a significant transformation with the introduction of innovative BFS solutions specifically tailored for intravenous (IV) and ampoule product manufacturing. These advancements are not just about enhancing the efficiency of medication delivery; they are about fundamentally changing how patients receive treatment. The BFS system leverages a state-of-the-art algorithm designed to ensure that medications are delivered with both precision and safety. Its streamlined approach mitigates the risks associated with traditional methods, ultimately enhancing patient care.

One of the standout features of the BFS solutions is their user-friendly design. Healthcare professionals can seamlessly incorporate this system into their workflow with minimal training, allowing for a quicker transition to this advanced technology. This ease of use is complemented by the affordability of the BFS system, making it an attractive option for hospitals and clinics looking to optimize their operations without sacrificing quality or safety. As healthcare providers explore new methods to improve patient outcomes, BFS solutions represent a promising step forward in the delivery of intravenous and ampoule therapies.

FAQS

: The primary focus should be on identifying your specific business needs, which includes assessing the types of products to be packaged, the production scale, and the regulatory standards in your industry.

Assessing experience is crucial as it can significantly impact your business's success; manufacturers with extensive experience can better navigate unique packaging challenges and ensure compliance with industry standards.

Look for manufacturers with a proven track record in BFS technology, ideally with at least 5-10 years of experience and a portfolio showing successful projects across various applications like pharmaceuticals, cosmetics, or food products.

Manufacturers investing in automation and advanced technologies typically demonstrate higher product output and reduced error rates, which are essential for maintaining quality standards.

Customization options ensure that the equipment meets unique operational goals and enhances production efficiency, catering specifically to the needs of your business.

Inquire about the types of machinery and technologies they employ, especially those that prioritize sustainable practices and can adapt to changing regulatory environments.

Partnering with a specialized manufacturer provides access to high-quality, reliable equipment and advanced technology, helping to enhance production efficiency and meet diverse industry demands.

The BFS technology market is expected to grow from USD 4.6 billion in 2020 to USD 6.7 billion by 2025, indicating a rising demand for efficiency and safety in packaging solutions.

Clearly articulated needs help narrow down potential manufacturers and evaluate their capabilities, ensuring you find a solution that aligns with your operational goals.

Industries such as pharmaceuticals, cosmetics, and food production can significantly benefit from BFS technology due to its efficiency, safety, and compliance with regulatory standards.

Conclusion

When you're trying to pick the right Blow Fill Seal manufacturers for your business, the first thing you really want to do is figure out what your specific needs are. Basically, understanding what you require will help you narrow down the options and focus on manufacturers who really know their stuff. It’s also super important to look into their quality standards and whether they follow the necessary regulations—nobody wants surprises down the line, right?

Plus, don’t forget to check out what kind of customization options they offer. Sometimes, tailoring solutions can make a huge difference for your unique business needs. Taking a look at customer reviews and case studies can give you a pretty good idea of how reliable they are and how they perform in real-world situations. And of course, you’ll want to consider costs and any long-term financial commitments so you can make a smart, well-informed choice that lines up with your business goals.

Here at Shanghai IVEN Pharmatech Engineering Co., Ltd., we're really proud of our high-quality solutions and our professional factories. We’re committed to making sure you get the best in blow fill seal technology, no matter what you need.

Related Posts

-

Unlocking Efficiency: The Transformative Benefits of Blow Fill Seal Machines in Modern Manufacturing

-

Empowering Global Trade: China's Premier Blow Fill Seal Ampoules Leading the Way

-

The Complete Ultimate Guide to Finding the Best Blow Fill Seal Manufacturers

-

Essential Checklist for Choosing the Right China Automatic Filling Machine for Pharmaceutical Applications

-

Ultimate Checklist for Choosing the Best Herb Extraction Machine for Your Business Needs

-

Innovative Solutions for Enhancing Quality Control with Automatic Vial Inspection Machines

Blog Tags: