Understanding the Functionality and Benefits of a Dry Filling Machine in Modern Industries

Table of Contents

- The Basic Principles of Dry Filling Machines in Industrial Applications

- Key Features of Dry Filling Machines That Enhance Efficiency

- Advantages of Utilizing Dry Filling Machines in Modern Manufacturing

- Comparative Analysis: Dry Filling vs. Other Filling Technologies

- Maintenance Tips for Optimal Performance of Dry Filling Machines

- Revolutionizing Beverage Production: The Essential Role of Syrup Washing, Filling, and Capping Machines

- FAQS

- Conclusion

- Related Posts

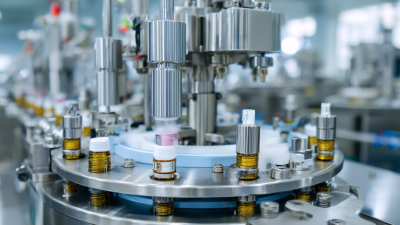

In today’s fast-moving industrial world, everyone’s chasing after better efficiency and tighter precision in their production lines. One piece of equipment that’s become pretty much essential in this race for excellence is the Dry Filling Machine. Now, Shanghai IVEN Pharmatech Engineering isn’t just any company—they've got four specialized factories focusing on everything from pharmaceutical machinery and blood collection tube equipment to water treatment solutions.

In this blog, I’ll walk you through how Dry Filling Machines work and why they’re such a game-changer. They help boost productivity, keep product quality steady, and even help businesses run more sustainably. Getting a better handle on these machines and their critical role can really help companies level up their manufacturing game and stay competitive in this tough market.

The Basic Principles of Dry Filling Machines in Industrial Applications

Dry filling machines are pretty essential in a lot of modern industries, especially when it comes to packaging powders and granules. Basically, these machines work by carefully measuring and filling bulk materials into containers or bags. They use some pretty smart tech—like gravity, augers, or vibratory systems—that helps ensure the correct weight and volume every time. That’s super important for keeping product quality consistent and meeting all those regulatory standards. Using these methods really helps make the filling process smoother and faster, which means better productivity overall.

When you’re choosing a dry filling machine, a good tip is to think about the type of material you’re working with. Things like particle size, how easily it flows, and moisture content can really impact how well the machine performs. It’s a smart move to do some tests beforehand — that way, you can find the setup that works best for your specific needs.

Another thing to keep in mind is how flexible these machines can be. Many models are designed to integrate seamlessly into your existing production line, which keeps things running without major hiccups. Plus, some machines come with features like automated controls, giving you real-time data and adjustments to keep the filling spot-on.

And don’t forget – regular maintenance and calibration are key. Giving your machine routine check-ups helps it last longer and perform reliably over time. What’s often overlooked is setting up a regular schedule for those maintenance tasks — it’s worth the effort to avoid unexpected downtime and keep the production line humming along without a hitch.

Industry Adoption of Dry Filling Machines

This chart illustrates the adoption rates of dry filling machines across various industries. The pharmaceutical and food & beverage industries show the highest adoption rates, reflecting the critical need for precision and efficiency in these sectors. In contrast, agriculture shows lower adoption, indicating potential areas for growth.

Key Features of Dry Filling Machines That Enhance Efficiency

Dry filling machines have really changed the game when it comes to packaging in so many industries. They’ve made things way more efficient and precise. One of the coolest features is how they incorporate cutting-edge tech—like digital weight displays and automated controls—which just streamlines the whole process. I recently read in a report by Market Research Future that the global market for these machines is expected to grow at around 4.5% annually from 2021 to 2027. And it makes sense, right? Increasing demand from sectors like pharma and food processing is really pushing things forward.

What’s also pretty impressive is how versatile these machines are. They can handle all sorts of products — powders, granules, beads, you name it. That flexibility means companies can tweak their production lines to be more efficient, cutting down on downtime and costs. The Packaging Machinery Manufacturers Institute (PMMI) even mentions that using the latest dry filling machines can bump up packaging efficiency by as much as 30%. No joke! As automation and precision become even more important, these machines are becoming essential for creating smooth and modern manufacturing processes.

Understanding the Functionality and Benefits of a Dry Filling Machine in Modern Industries - Key Features of Dry Filling Machines That Enhance Efficiency

| Feature | Description | Benefits |

|---|---|---|

| High Precision Weighing | Utilizes advanced load cells for accurate measurement of dry ingredients. | Reduces material waste and ensures product consistency. |

| Speed Control | Adjustable filling speed to match production requirements. | Improves overall throughput and efficiency in operations. |

| Automated Calibration | Features automated calibration procedures for easy setup and maintenance. | Minimizes downtime and reduces manual error. |

| Multi-Product Capability | Can handle various dry materials like powders, grains, and granules. | Increases versatility for diverse product lines. |

| User-Friendly Interface | Intuitive controls and touch screen for easy operation. | Enhances user experience and ease of training for operators. |

| Hygienic Design | Constructed with easy-to-clean materials and surfaces. | Ensures compliance with food safety standards. |

Advantages of Utilizing Dry Filling Machines in Modern Manufacturing

You know, in today's manufacturing world, dry filling machines are pretty much game-changers. They really help boost efficiency and precision across different industries. Honestly, they make the whole process of filling powders and granules into containers so much easier — you get consistent weight and volume, and it cuts down on waste too. Plus, with their automation features, there's less need for people to do the tedious manual work, which means things move faster and costs go down. It's kind of cool how adopting the latest tech not only makes production more efficient but also helps companies reduce energy use and emissions — totally in line with the push for greener manufacturing practices.

And get this, recent breakthroughs in drying tech are only making things better. Like, they’ve improved seed and grain drying systems, which shows how traditional methods are getting a modern upgrade for cleaner, more efficient production. Oh, and there are now super user-friendly options, like small, desktop powder auger fillers. These are perfect for small manufacturers or labs that want high-quality filling but don’t need giant machines. As industries keep evolving, it’s clear that dry filling machines are vital for keeping operations smooth and meeting what the market demands. Honestly, they’re pretty indispensable these days.

Comparative Analysis: Dry Filling vs. Other Filling Technologies

Hey, you know, when it comes to modern industries, choosing the right filling technology can really make a difference in how efficient things are and the overall quality of the products.

Dry filling machines, in particular, are pretty awesome—they handle powders and granules with a level of precision that sets them apart from other methods like liquid or paste filling.

I mean, if you look at it closely, liquid filling does great with fluids, but dry filling is the go-to when you absolutely need to keep moisture content as low as possible.

Take food or pharma, for example—keeping that product dry and intact is super important, which is why dry filling machines are usually the better choice.

When you're thinking about the perks of dry filling machines, it’s also worth noting how versatile they are. They can work with all sorts of materials, even those that don’t flow so easily. Recently, some studies have dived into how these powders and granules compact under pressure, giving us a better idea about their physical behaviors in different situations.

Plus, as industries keep evolving, we're seeing more advanced tech being integrated—like fluidized filling for tricky materials such as coal gangue—pushing toward more efficient, eco-friendly ways of handling materials.

A couple of tips that might help you out: regularly keep an eye on your material properties because even small changes can throw off your filling process.

And if you can, try implementing machine vision tech—it really helps make quality control smoother and cuts down on mistakes. Lastly, staying updated on the latest advancements in filling tech will give you a leg up, helping your operations stay competitive and up to industry standards.

It’s all about keeping things running as smoothly and reliably as possible!

Maintenance Tips for Optimal Performance of Dry Filling Machines

When it comes to keeping your dry filling machines in good shape, staying consistent is really the secret to making sure they run smoothly and last longer. Doing regular check-ups can save you from unexpected breakdowns that could cost a pretty penny, and it also helps keep your production line running efficiently. I’d suggest starting with routine inspections of all the mechanical parts—things like the filling nozzles, hoppers, and conveyor systems. Just making sure these are clean and free of any debris will not only improve the accuracy of your filling process but also give your equipment a longer lifespan.

Oh, and don’t forget about calibration! Basically, periodically adjusting those settings to ensure the volume is spot-on is super important. It helps you meet industry standards and keeps your customers happy. Setting aside a little time to calibrate and test the machine now and then really pays off in better performance and top-quality products.

Lastly, using good quality lubricants on all moving parts is a simple step that can make a big difference. Proper lubrication cuts down friction and wear, which means fewer breakdowns down the road. Just be sure to follow the manufacturer’s guidelines on how often and what type of lubricant to use—that way, your machine stays reliable and efficient for its long haul.

Honestly, if you follow these tips, you’ll notice a real improvement in how your dry filling machines operate, and they'll be able to keep up with your production needs without a hitch.

Revolutionizing Beverage Production: The Essential Role of Syrup Washing, Filling, and Capping Machines

In the modern beverage industry, efficiency and innovation play pivotal roles in production processes. The Syrup Washing, Filling, and Capping Machine exemplifies this trend by integrating multiple functions into a single, compact unit. This revolutionary machine not only performs high-quality syrup bottle air or ultrasonic washing but also facilitates either dry syrup or liquid syrup filling, followed by an automatic capping process. This all-in-one design significantly reduces the need for separate machines, leading to lower investment and production costs.

The compact structure of this equipment is another noteworthy advantage, as it occupies minimal space and requires fewer operators, making it ideal for small to medium-sized production lines. Moreover, the potential for integrating bottle handling and labeling machines further enhances its functionality, allowing for a seamless production line. By opting for this advanced solution, beverage manufacturers can streamline their operations, improve their efficiency, and ultimately enhance their product output in an ever-competitive market.

FAQS

: Dry filling machines operate by accurately measuring and dispensing bulk powders and granulates into containers or bags, utilizing technologies like gravity, augers, or vibratory mechanisms to ensure precise weight and volume.

Key factors include the material properties of the product, such as particle size, flowability, and moisture content, which can significantly affect the machine's performance.

They enhance efficiency and precision by streamlining the filling process, reducing waste, lowering the need for manual labor, and incorporating automation to increase production speed and operational cost-effectiveness.

Regular maintenance and calibration are essential to ensure longevity and consistent performance. Establishing a routine schedule for checks and adjustments can help minimize unexpected downtime.

Dry filling machines excel in handling powders and granules, especially in applications where minimizing moisture content is critical, making them more suitable than liquid or paste filling technologies in sectors like food and pharmaceuticals.

Recent innovations include improved drying technologies, user-friendly designs like compact desktop powder auger machines, and advanced systems like fluidized filling, which enhance production processes and sustainability.

Automated control systems with real-time monitoring capabilities allow for adjustments to optimize filling accuracy, ensuring product consistency and compliance with regulatory standards.

Regular monitoring of material characteristics is crucial as variations can affect the filling performance. This helps maintain efficiency and product quality.

Implementing machine vision technology can streamline quality control in filling operations, reducing the risk of filling errors and ensuring product standards are met.

As industries strive for sustainability, advanced technologies that recycle energy and reduce emissions are increasingly integrated into dry filling machines to align with modern environmental standards.

Conclusion

In today's manufacturing world, the Dry Filling Machine has really become a game-changer. It boosts productivity and efficiency across a bunch of industries. If you get to know the basics of how these machines work, you can really take advantage of their main features—like precise filling, quick operation, and automation. These things make a huge difference, helping production lines run smoother, resulting in more products made and lower costs overall.

And honestly, the benefits of using Dry Filling Machines compared to other filling methods are pretty clear. They can handle all kinds of dry products while wasting less material. Companies like Shanghai IVEN Pharmatech Engineering Co., Ltd., with their experience in pharma machinery, really know how crucial these machines are for keeping things running efficiently. Plus, a little regular maintenance can go a long way in keeping them in top shape. All in all, investing in a Dry Filling Machine seems like a smart move for modern industries looking to get more reliable and efficient operations going.

Related Posts

-

Navigating Import Export Certifications for Best Pen Injector Assembly Line Success

-

7 Essential Tips for Choosing the Right Blow Fill Seal Manufacturers for Your Business

-

Ultimate Checklist for Selecting the Right Vial Filling Equipment

-

Exploring 2025's Transformative Trends in Pharmaceutical Manufacturing: How to Optimize Your Vial Filling Equipment

-

The Complete Ultimate Guide to Finding the Best Blow Fill Seal Manufacturers

-

Essential Checklist for Choosing the Right China Automatic Filling Machine for Pharmaceutical Applications

Blog Tags: