Ultimate Guide to Choosing the Right Tube Labeling Machine Suppliers for Your Business Needs

Table of Contents

- Key Features to Look for in Tube Labeling Machines

- Understanding Different Tube Labeling Technologies

- How to Evaluate Tube Labeling Machine Suppliers

- Top Questions to Ask Potential Suppliers Before Buying

- Common Mistakes to Avoid When Choosing a Tube Labeling Machine

- Cost vs. Quality: Finding the Right Balance for Your Business

- Streamlining Healthcare Efficiency: The Essential Role of a Vacuum Blood Collection Tube Production Line

- FAQS

- Conclusion

- Related Posts

In today’s super competitive world, picking the right Tube Labeling Machine Supplier is a pretty important decision for any business in the pharma industry. With the demand for more efficient labeling tools on the rise, companies really need to weigh their options carefully—looking at things like the supplier’s expertise, the quality of their products, and the kind of support they offer. Shanghai IVEN Pharmatech is actually a name that tends to stand out in this space. They’ve got four dedicated factories that focus on pharmaceutical machinery, blood collection tube equipment, and water treatment systems. By zeroing in on precision and innovation, IVEN makes sure businesses get top-of-the-line labeling machines that can really boost efficiency. This guide’s gonna take you through the main stuff you should keep in mind—things like what to consider and best practices—so you can pick a supplier that really hits the mark for your specific needs. Basically, it’s all about helping you make smarter choices to grow your business without the headache.

Key Features to Look for in Tube Labeling Machines

When you're looking at choosing a tube labeling machine, there are a few key things you really want to consider to make sure it fits your business perfectly.

For starters, the speed and accuracy of the machine are a big deal. Industry folks say that machines rocking speeds over 150 units per minute can seriously boost your productivity — plus, if they’re accurate over 99%, you're good on compliance, especially in hot sectors like pharma or food where a mislabel can cause big trouble.

Another thing to keep in mind is how versatile the machine is. If it can handle different tube sizes and materials, that’s a big plus because it means you can shift your product lines around without constantly swapping out equipment or facing long downtimes.

Apparently, versatile machines can cut operational costs by around 30%, since you're not stuck with buying and maintaining multiple devices. Plus, newer machines with simple interfaces and automation features can really help speed things up — less time, less labor, more consistency.

All these points are super important when picking out your supplier. The right features make a big difference in how smoothly your production runs and how easily you can grow or adapt in the future.

Understanding Different Tube Labeling Technologies

When you're on the hunt for a tube labeling machine for your business, it’s pretty important to get a good handle on the different labeling technologies out there. You’ve got your main options like roll-fed, shrink sleeve, and pressure-sensitive labels. I recently came across some market reports that show pressure-sensitive labels are really on the rise—growing by over 8% each year—mainly because they’re super easy to use and work well in all kinds of settings. On the other hand, roll-fed systems, which use a continuous roll of labels, tend to be the go-to choice for high-speed production lines, especially if you’re dealing with large volumes.

Here's a quick tip: Before you pick out your machine, think about your production needs—specifically, how many labels you need and how fast you'll need them applied. Figuring this out early on helps you choose the most efficient tech for your situation.

These days, with tech moving so fast, automation and custom features are totally changing the game. They not only make labeling more accurate, but they can also cut down on labor costs. For example, RFID-enabled systems can make your inventory management way easier—they use smart labels that send data directly to your management system right away. The upside? Better tracking and fewer mistakes, which can seriously boost your operation’s efficiency.

Pro tip: Think ahead and consider how your labeling process might need to grow in the future. Going for machines that are compatible with new tech now can save you a headache and money down the line.

How to Evaluate Tube Labeling Machine Suppliers

When you're trying to pick out the right tube labeling machine supplier for your business, it’s super important to do some homework on their credibility and what they offer. Start by digging into their reputation in the industry—yeah, look up online reviews and testimonials from other companies that have worked with them. A trustworthy supplier will usually have a track record of happy customers and successful projects under their belt. And hey, don’t hesitate to ask for references or case studies that show off their skills in providing labeling solutions.

Here’s a tip: try to find suppliers that offer tailored solutions that actually fit what you need. The more they understand the specific quirks of your business, the better they can help make your labeling process smooth and hassle-free. Also, give some thought to their support services. A supplier that provides training, maintenance help, and good customer support means you'll have someone to turn to whenever issues pop up—especially down the line.

And before making any final decisions, check their warranty and service agreements. A solid warranty shows they believe in the quality of their equipment, and good service agreements mean you’re covered if anything goes wrong. This stuff really helps protect your investment and makes your long-term labeling operations run a lot more smoothly. Bottom line—choose wisely so you can keep things running efficiently and boost your overall productivity.

Top Questions to Ask Potential Suppliers Before Buying

When you're on the hunt for a tube labeling machine supplier, it's really important to ask the right questions so you’re sure they can actually meet what your business needs. A good starting point is to peek into their manufacturing processes. Industry reports often show that suppliers with solid, standardized workflows tend to be more reliable — so it’s worth digging into their production capabilities and how they handle quality control. Also, pay attention to how quickly they respond and how flexible they are; these little things can tell you a lot about how efficient they are and how they treat their customers.

Another thing to consider is their commitment to ethical practices. After all, with the supply chain messes we saw during the pandemic, trust is more important than ever. It’s a good idea to ask about their sustainability efforts and how they handle ethical sourcing. Turns out, suppliers who really focus on sustainability tend to boost their reputation and are more in tune with what customers want these days — responsible business and all that.

All in all, taking a strategic approach when chatting with potential suppliers can really lay the groundwork for a solid partnership. Don’t forget to ask if they can grow with you down the line — because building a long-term relationship can really help your business thrive and stay agile in today’s competitive market.

Common Mistakes to Avoid When Choosing a Tube Labeling Machine

When you're on the hunt for a tube labeling machine supplier, it’s pretty common for businesses to trip up on the same kinds of mistakes that can really hurt their workflow. One thing a lot overlook is just how important a supplier’s reputation and experience really are. I mean, a study from the Manufacturing Institute shows that about 83% of successful companies say they prioritize supplier reliability when making purchasing decisions. Skipping the research step and jumping into a partnership with a less-than-reliable company can lead to issues like poor service or low-quality products—that’s a headache nobody needs.

Another often-overlooked detail is whether the machine actually fits with your existing setup. The Packaging Machinery Manufacturers Institute points out that around 65% of production hiccups happen because of mismatched equipment. It’s totally essential to double-check that the labeling machine you pick can work smoothly with your current lines—otherwise, you risk messing with your whole process. And don’t forget about after-sales support. A good, trustworthy supplier will stick around to help out if something goes wrong. Ignoring this can mean costly downtimes that drag down your productivity. So yeah, steering clear of these common pitfalls can really make a difference in how well your labeling operations run, and save you a lot of headaches in the long run.

Cost vs. Quality: Finding the Right Balance for Your Business

When you're on the hunt for tube labeling machine suppliers, one of the biggest things to keep in mind is finding that sweet spot between cost and quality. Sure, it’s tempting to just go for the cheapest option out there, but trust me, it’s worth digging a little deeper to see what you’re really getting for that price. A machine that costs less upfront might seem like a bargain, but it could end up breaking down more often, racking up maintenance costs, and dragging down your productivity in the end. Spending a bit more on a good-quality machine might seem like a splurge at first, but in the long run, it pays off because you get reliability, faster operation, and more accurate labeling—all things that matter a lot.

On top of that, higher-quality machines usually come with some pretty cool tech and features that can seriously boost your production line's efficiency. They tend to be more precise and adaptable—perfect for handling different tube sizes and types without a ton of fuss. That can save you a bunch of time and hassle, not to mention money on re-adjustments or staff training. It’s a good idea to do your homework here—check out reviews, ask around, maybe even get some feedback from other users. Finding a supplier that offers good value without skimping on quality can make a real difference, helping your business stay smooth and effective without breaking the bank.

Ultimate Guide to Choosing the Right Tube Labeling Machine Suppliers for Your Business Needs

| Supplier Type | Cost ($) | Quality Rating (1-10) | Lead Time (Weeks) | Customer Support Rating (1-5) |

|---|---|---|---|---|

| Domestic Manufacturer | 5000 | 9 | 4 | 5 |

| International Supplier | 3500 | 8 | 6 | 4 |

| Local Distributor | 4000 | 7 | 3 | 5 |

| Online Retailer | 4200 | 6 | 2 | 3 |

| Wholesale Supplier | 3000 | 5 | 5 | 4 |

Streamlining Healthcare Efficiency: The Essential Role of a Vacuum Blood Collection Tube Production Line

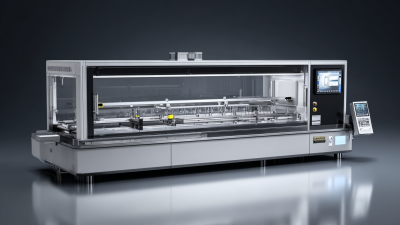

In the quest to streamline healthcare efficiency, the role of a vacuum blood collection tube production line is indispensable. This state-of-the-art line ensures that the entire process, from tube loading to final packaging, is both efficient and reliable. With components such as chemical dosing, drying, stoppering and capping, and vacuuming, each stage of production is meticulously designed to maintain high standards of quality and safety.

One of the standout features of this production line is its ease of operation, thanks to individual PLC (Programmable Logic Controller) and HMI (Human-Machine Interface) controls. This advanced technology allows for a seamless workflow that not only maximizes output but also minimizes the chances of error. With a requirement of only 2-3 trained workers to operate the entire system, healthcare facilities can significantly reduce labor costs while enhancing productivity.

Moreover, the versatile design of the vacuum blood collection tube production line caters to the diverse needs of healthcare providers. The efficient tray loading system further optimizes the packaging process, ensuring that the tubes are ready for distribution without delay. This integrated approach not only saves time and resources but also contributes to improved patient care by facilitating quicker diagnostics and treatment.

FAQS

: The primary tube labeling technologies include roll-fed, shrink sleeve, and pressure-sensitive labeling.

Pressure-sensitive labeling applications have grown by over 8% annually due to their ease of use and versatility in various settings.

Always assess your production volume and speed requirements to determine which labeling technology offers the best efficiency for your needs.

Automation and customization offer increased accuracy and reduced labor costs, with technologies such as RFID improving inventory management and tracking accuracy.

Inquire about their manufacturing processes, quality control measures, responsiveness, flexibility, and commitment to ethical practices and sustainability.

While opting for lower-priced machines may be tempting, they can lead to frequent breakdowns and higher maintenance costs, ultimately affecting productivity.

Quality labeling machines offer advanced technology, better precision, adaptability for various tube sizes, and can save time and money on adjustments and training.

Assess their capacity to scale with your future needs and their commitment to ethical practices, as this establishes trust and can enhance your business's growth.

Investing in a higher-priced, quality machine can ensure reliability, speed, and accuracy, contributing to operational effectiveness and long-term savings.

Conclusion

Picking the right tube labeling machine supplier is actually pretty important for any business in pharma and related fields. When you're shopping around, it’s good to think about some key stuff—like how fast the machine works, how accurate it is, and whether it can handle different tube sizes without a hitch. Getting to know the different labeling tech out there can really help you figure out which solution fits your needs best.

Also, when you’re evaluating potential suppliers, don’t forget to ask the right questions—like how much experience they have, what kind of support they provide after the sale, and if they offer custom options for their machines. One common mistake folks make is focusing too much on cost and forgetting about quality, which can end up hurting your efficiency down the line. By weighing these factors carefully, you can make smarter decisions and team up with reputable suppliers—like Shanghai IVEN Pharmatech Engineering Co., Ltd.—who specialize in top-notch machinery tailored for pharma businesses.

Related Posts

-

Top Strategies for Ensuring the Validation of Capsule Filling Machines in Pharmaceutical Production

-

Empowering Global Markets with Premier Chinese Vial Cap Sealing Machine Innovations

-

Innovative Solutions for Enhancing Quality Control with Automatic Vial Inspection Machines

-

Understanding the Essentials of Automated Filter Tube Production Techniques

-

Advantages of Using the Best Bosch Vial Filling Machine for Your Production Efficiency

-

The Future of Liquid Filling Machines: Innovations Shaping Tomorrow's Manufacturing

Blog Tags: