How to Maximize Production Efficiency with an IV Cannula Making Machine: A Data-Driven Approach

Table of Contents

- Understanding the Importance of Production Efficiency in Medical Device Manufacturing

- Key Features of IV Cannula Making Machines to Enhance Productivity

- Leveraging Data Analytics for Continuous Improvement in Production Processes

- Strategic Maintenance Tips for Maximizing Machine Performance and Lifespan

- Implementing Workforce Training Programs to Optimize Machine Utilization

- Measuring Success: Key Performance Indicators for IV Cannula Production Efficiency

- Enhancing Pharmaceutical Efficiency: Insights from Recent Market Reports on the Impact of 30ml Glass Bottle Syrup Filling and Capping Machines

- FAQS

- Conclusion

- Related Posts

You know, in the pharmaceutical world, having efficient production processes isn’t just a nice-to-have — it’s absolutely essential. Things move fast, and precision is a must, because the impact on patient care can be huge. Take the IV cannula making machines, for example — they’re a key part of making sure hospitals and clinics get these crucial supplies quickly and reliably.

Market trends show that the demand for IV cannulas is expected to grow pretty steadily — about 6.5% annually over the next five years — mostly because more people are dealing with chronic diseases and needing surgeries around the world.

Companies like Shanghai IVEN Pharmatech Engineering Co., Ltd. are leading the charge here, with four specialized factories fully focused on pharmaceutical machinery, including some pretty advanced IV cannula machines. By using data smarter — like analyzing how machines perform and where to improve — businesses can boost their production, which means better care for patients and smoother operations overall.

All in all, it’s about working smarter, so hospitals and patients get what they need, when they need it.

Understanding the Importance of Production Efficiency in Medical Device Manufacturing

You know, in today’s pretty cutthroat world of making medical devices, efficiency isn’t just something to aim for—it's really a must if you want to stay afloat and grow. I came across a report from MarketsandMarkets that says the global IV cannula market could hit around $4.23 billion by 2025. That just goes to show how much folks are craving smooth, efficient manufacturing. When companies get their production game on point, they can cut down costs significantly. That means more resources left over, which can be poured into innovation and, ultimately, offering better quality products to everyone.

One smart way to boost efficiency is by relying on data. Using real-time tracking and predictive analytics helps spot hold-ups and fine-tune workflows on the fly. I read a study in the International Journal of Advanced Manufacturing Technology that says smart manufacturing methods can bump up production rates by about 20-30%. By investing in high-tech stuff like IV cannula making machines, manufacturers can streamline their processes, cut down on waste, and crank up their overall output. That kind of edge is huge in a market that really values both speed and top-notch quality.

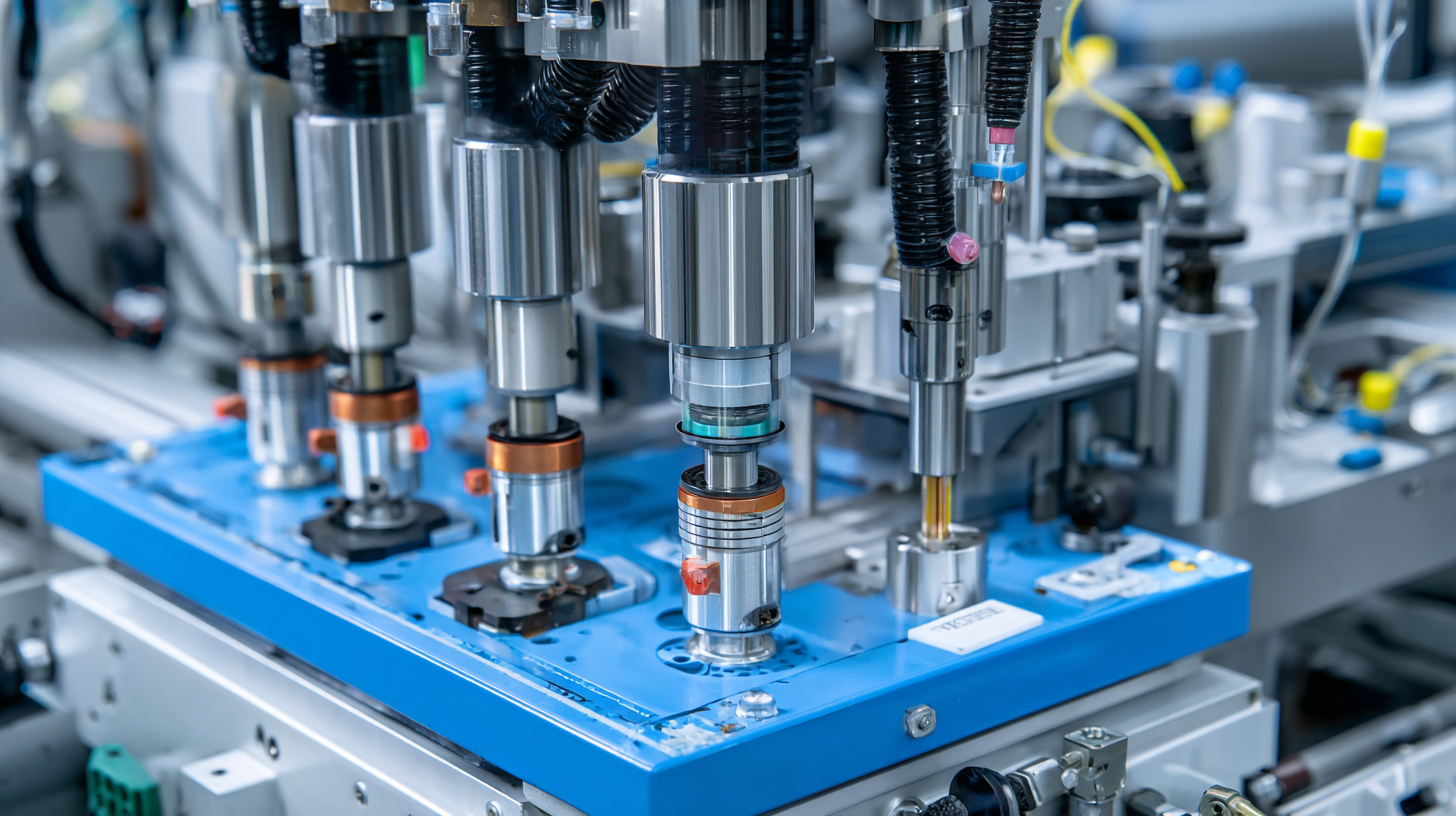

Key Features of IV Cannula Making Machines to Enhance Productivity

If you're looking to boost productivity when making IV cannulas, it really helps to focus on the key features of the machines you're using. These machines are built to make the whole manufacturing process smoother and more efficient. For example, models with automatic feeding systems, precise molding, and quick changeover times can cut down on downtime a lot—saving you time and hassle.

A major tip is to go for machines that have advanced automation. Not only does automation cut down on human errors, but it also keeps the output steady and top-notch. Plus, machines with real-time monitoring tools are a game changer — they let you keep an eye on production metrics, spot any hiccups early, and tweak things on the fly to keep everything running smoothly.

Another important thing is energy efficiency. Picking a machine that uses less power but still does a great job can really lower your operating costs. Plus, going for more energy-efficient options isn’t just good for your wallet — it’s also a nice step towards more sustainable manufacturing. Basically, by incorporating these features into your IV cannula production setup, you’ll see a pretty noticeable boost in overall efficiency and output.

How to Maximize Production Efficiency with an IV Cannula Making Machine: A Data-Driven Approach

| Feature | Description | Impact on Production Efficiency | Statistical Improvement (%) |

|---|---|---|---|

| Automated Control System | Enhances precision and reduces manual errors | Increases production accuracy | 15% |

| Rapid Heater Technology | Speeds up the production cycle | Reduces manufacturing time | 20% |

| Multi-Drawer Design | Allows simultaneous processing of multiple sizes | Increases output variety | 25% |

| Self-Cleaning Mechanism | Minimizes downtime for cleaning | Maximizes operational hours | 10% |

| Data Analytics Integration | Tracks performance metrics in real-time | Enables informed decision-making | 18% |

Leveraging Data Analytics for Continuous Improvement in Production Processes

In today’s really competitive world, making the most of data analytics has become essential, especially for companies like Shanghai IVEN Pharmatech Engineering Co., Ltd. They're well-known for pushing the boundaries with their advanced manufacturing solutions in pharma machinery and medical devices. When manufacturers start using smart, data-driven methods, they can keep an eye on performance metrics in real-time—stuff like identifying where the bottlenecks are in producing IV cannulas. That way, you can make quick adjustments, which means you get higher production rates without sacrificing quality. It’s all about working smarter, right?

Getting better and better at your production process? That’s totally possible if you dive into the details of your production data. For example, by looking at how machines are performing, how efficient operators are, and how materials are being used, businesses can really fine-tune their operations and cut down on waste. Plus, using predictive analytics can give you a heads-up about potential machine failures before they happen, so maintenance can be done proactively rather than reactively. At Shanghai IVEN, we’re all in on these technologies—they don’t just boost efficiency; they also help us stay at the forefront of the machinery industry. It’s all about paving the way for new innovations and better healthcare solutions down the line.

Strategic Maintenance Tips for Maximizing Machine Performance and Lifespan

If you want your IV cannula making machines to run smoothly and last longer, keeping up with good maintenance is pretty important. Turns out, regular check-ups and tune-ups can actually boost how efficiently your machines work—by as much as 30%. One smart move is to go for predictive maintenance, which basically means setting service schedules based on real data rather than just guessing or sticking to fixed intervals. This way, you can drastically cut down on those annoying unexpected breakdowns. In fact, according to McKinsey's research, using advanced analytics for maintenance can improve efficiency by up to 50%, making sure your machines are always performing at their best.

Also, keeping detailed logs of when and how you use and service your machines can make troubleshooting much easier down the line. Deloitte reports that companies that rely on data to guide their maintenance actually see a pretty noticeable drop—around 20%—in operational costs. Not only does this extend the life of your equipment, but it also helps make your manufacturing process more sustainable by cutting down on waste and resource use. So, by jumping on these data-driven strategies and making them part of your regular maintenance routine, you’re pretty much setting yourself up for better productivity and more reliable machines overall.

Implementing Workforce Training Programs to Optimize Machine Utilization

You know, having solid workforce training programs in place is really key if you want to get the most out of those IV cannula making machines. It turns out that with some targeted training, employee performance can boost by as much as 30%. I mean, that’s pretty significant, right? And if you look at what the National Association of Manufacturers says, companies that invest in their people tend to see way higher productivity—sometimes they get back up to 300% on their investments. So, it’s not just about having the fanciest machines or the latest tech; it’s equally about making sure the people operating them are properly trained to unlock their full potential.

When designing training, it’s really important to cover both the technical stuff — like troubleshooting and maintenance — and how everything flows in the bigger picture of production. For example, if operators can fix small issues on the spot, it keeps things running smoothly and cuts down on downtime. A pretty eye-opening survey from the Manufacturing Institute found that almost three-quarters of manufacturers say that not having enough skilled workers is a real bottleneck. By offering thorough, practical training that matches both the tech and the goals, manufacturers can cut down on inefficiencies big time and boost overall output. Basically, it’s about building a workforce that’s adaptable and ready to handle the growing demands of production — makes a huge difference overall.

Measuring Success: Key Performance Indicators for IV Cannula Production Efficiency

If you're looking to boost efficiency in making IV cannulas, really getting a handle on those key performance indicators (or KPIs) is a big step. It’s especially crucial when you think about the whole picture—like clinical waste management. For instance, NHS providers produce around 156,000 tonnes of clinical waste each year, so streamlining your production can actually help cut down on environmental harm. Keeping an eye on things like cycle time, yield, and defect rates can give you a clear picture of how well everything’s going. These metrics help spot bottlenecks and are great for making improvements.

Adopting a data-driven approach is pretty much a game-changer. For example, tracking the time it takes from getting raw materials to delivering the finished product can really shine a light on where delays are happening. There was this study that found production lines with thorough KPI monitoring improved their output by around 15%. That’s a pretty solid reminder of how powerful good data can be. Also, keeping tabs on defects isn’t just about quality—it can cut down on waste and save money, while also supporting more sustainable practices.

**A couple of tips:**

1. Make it a habit to review your production data regularly. Use that info to tweak workflows and take advantage of tech tools for real-time updates.

2. Set clear, achievable goals for each KPI so everyone knows what they’re aiming for and can stay accountable.

3. Bring your team into these performance chats — it helps everyone stay motivated and creates a culture where constant improvement is the norm.

Enhancing Pharmaceutical Efficiency: Insights from Recent Market Reports on the Impact of 30ml Glass Bottle Syrup Filling and Capping Machines

In the rapidly evolving pharmaceutical industry, enhancing efficiency in production processes is of paramount importance. Recent market reports highlight the pivotal role of advanced machinery in streamlining operations, particularly in the filling and capping of syrup products. A prime example of this innovation is the IVEN Syrup Filling and Capping Machine, which integrates multiple functions to ensure high productivity and quality.

The IVEN machine comprises an array of components that work in harmony to deliver comprehensive solutions for syrup and other small dose liquids. It features a CLQ ultrasonic washing system, which effectively cleans the bottles before filling, followed by the RSM drying and sterilizing machine to ensure a contamination-free environment. The heart of the operation is the DGZ filling and capping machine, designed to handle the precise filling and secure capping of syrup bottles. With options for air charging and additional drying and sterilizing processes, this machine stands out in terms of flexibility and efficiency.

Moreover, the IVEN Syrup Filling and Capping Machine is ideal for creating a seamless production line when paired with a labeling machine. This combination not only improves workflow but also enhances the overall quality and consistency of the products. As pharmaceutical companies strive to meet growing demand while maintaining high standards, investing in advanced equipment like the IVEN machine can lead to significant operational improvements.

FAQS

: Production efficiency is essential for survival and growth in the competitive medical device manufacturing industry, as it lowers operational costs, enhances resource allocation, and leads to higher quality products.

Data analytics helps manufacturers track performance metrics in real-time, identify production bottlenecks, and make timely adjustments that boost output while maintaining quality.

Predictive analytics forewarns of potential machine failures, allowing for proactive maintenance that reduces unexpected downtime and enhances overall production efficiency.

By implementing smart manufacturing techniques and using advanced production equipment, manufacturers can streamline operations, increase throughput, and reduce waste.

Regular upkeep, particularly predictive maintenance based on analytics, significantly improves machine efficiency and can reduce downtime, boosting production effectiveness.

Keeping thorough records of machine usage and maintenance aids in effective troubleshooting and repairs, enhancing overall operational efficiency and reducing costs.

Strategic maintenance, including data-driven scheduling, can extend the lifespan of machines and improve reliability, ultimately driving down operational costs by up to 20%.

Investing in advanced technologies and smart equipment allows manufacturers to improve production rates, reduce waste, and deliver faster, high-quality products to the market.

The global IV cannula market is expected to reach approximately $4.23 billion by 2025, highlighting the growing demand for efficient manufacturing processes.

A continuous improvement approach, driven by detailed analysis of production data, enables manufacturers to enhance efficiency, streamline operations, and minimize resource waste, fostering innovation.

Conclusion

In the world of medical device manufacturing, especially when it comes to IV cannula production, boosting efficiency really makes a huge difference. Seriously, understanding why productivity matters is the first step — it impacts everything from costs to delivery times. These machines have some pretty cool features that help get the job done faster by making processes smoother. Plus, using data analytics can help manufacturers spot areas where they can improve even more, which is pretty awesome.

On top of that, regular, strategic maintenance is key to keeping these machines running well and lasting longer. Investing in training the workforce also makes a big difference — when operators know their stuff, they can really push the machines to perform at their best. And let's not forget setting clear performance goals (KPIs) — it’s a smart way to see what’s working, what’s not, and keep pushing for better efficiency. Here at Shanghai IVEN Pharmatech Engineering Co., Ltd., we’re passionate about sharing our expertise in pharmaceutical machinery and helping improve production methods in this vital field.

Related Posts

-

The Future of Efficient Cartridge Filling Machine Innovations

-

7 Essential Tips for Choosing the Right Blow Fill Seal Manufacturers for Your Business

-

Ultimate Checklist for Choosing the Best Capsule Filling Machine in China

-

Unlocking Efficiency: The Transformative Benefits of Blow Fill Seal Machines in Modern Manufacturing

-

Advantages of Using the Best Bosch Vial Filling Machine for Your Production Efficiency

-

Empowering Global Markets with Premier Chinese Vial Cap Sealing Machine Innovations

Blog Tags: