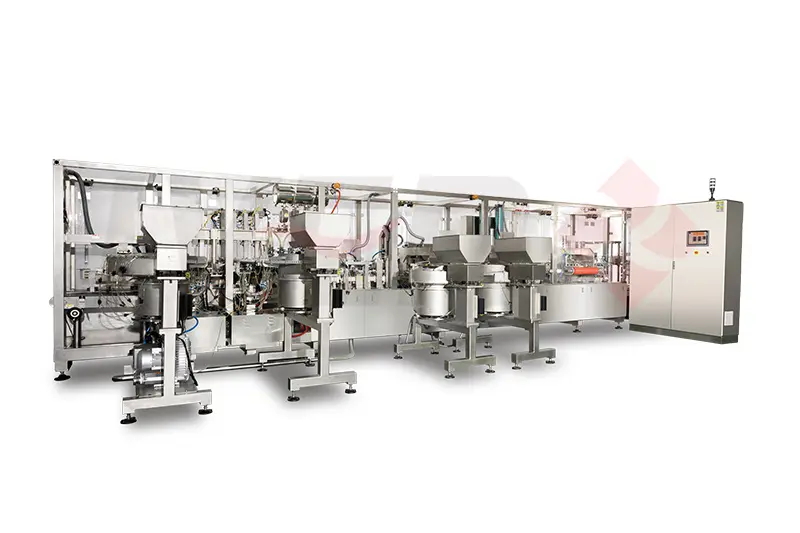

In the field of medical equipment manufacturing, the performance of peritoneal dialysis fluid production lines is directly related to the safety and reliability of the products. Our peritoneal dialysis fluid production line adopts advanced design concepts, with a compact structure and small footprint. It can efficiently complete key processes such as printing, forming, filling and sealing, pipe welding, and PVC bag making for peritoneal dialysis fluid bags, meeting the stringent requirements of modern production.

♦ Intelligent control, data traceability

The production line integrates multiple functions such as welding, printing, filling, CIP (online cleaning), and SIP (online sterilization). All key parameters (such as temperature, time, pressure, etc.) can be flexibly adjusted and saved in real time through the human-machine interface (HMI), ensuring the controllability and traceability of the production process. Operators can access historical data at any time as needed and support printing and output for quality review and production management.

♦High precision transmission and filling system

Servo motor+synchronous belt drive: The main drive system adopts a combination of high-precision servo motor and synchronous belt to ensure smooth operation, accurate positioning, effectively reduce errors, and improve production efficiency of the equipment.

Precision filling of quality flow meters: Equipped with advanced quality flow meters, the filling accuracy is high and the error is minimal. At the same time, it supports easy adjustment of filling volume through human-machine interface to meet the production needs of different specifications of products.

♦Multi functional integrated production

This production line is specially designed for the production optimization of peritoneal dialysis fluid bags, and can efficiently complete the following processes:

●Printing and Forming: Automatically complete the identification printing and bag body forming of dialysate bags.

●Filling and sealing: The high-precision filling system ensures accurate drug dosage, tight sealing, and eliminates the risk of leakage.

●Pipe welding: Advanced welding technology is used to ensure that the pipeline connection is firm and sterile.

●PVC bag making: Fully automatic bag making process ensures the sealing and durability of the bag body.

Our peritoneal dialysis fluid production line provides an efficient and reliable solution for medical dialysis fluid production with its compact design, intelligent control system, and high-precision filling and transmission technology. Whether it is parameter adjustment, data traceability, or precise filling and aseptic control, this production line can perform excellently, helping enterprises improve product quality and production efficiency.

If you need to learn more technical details or customized solutions, please feel free to contact us at any time!

Post time: Apr-25-2025